Information

- The Sano Plant has begun operations.

- Our Collaborative Robot Welding System Is Now in Operation

- We Have Relocated Our Head Office

- “Y’s Cafe” Now Open

Dear person in charge,

Do you have any of these concerns?

- I’d like to make just one prototype first.

- We need to secure the parts urgently within the next few days.

- We were turned down because they couldn’t achieve the required precision.

- The delivered parts have inconsistencies in precision.

- We want to reduce costs without compromising quality or precision.

Leave it to Yamada, with our proven track record!

Why Yamada is Chosen

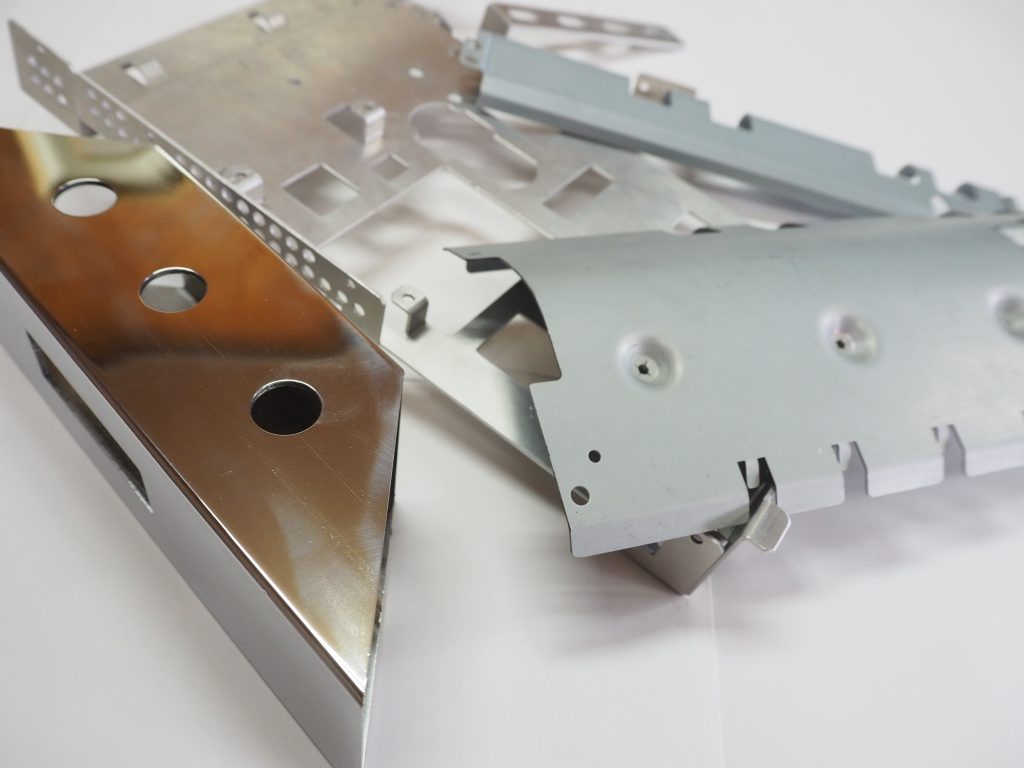

From low-volume to high-volume production

For over half a century, we have handled numerous prototypes. The transition to mass production is also seamless.

Quick delivery possible

From blanking, bending, welding and assembly to delivery, everything is completed in-house, enabling shorter lead times.

High quality and low cost

Through integrated production, we deliver quality recognized by listed companies, while keeping costs low.

Why can Yamada make it possible?

That’s because …

Through proactive capital investment, we are able to handle high-difficulty processing that can only be achieved with the latest equipment.

Through skilled craftsmanship, we achieve production that accommodates small-lot, high-mix orders.

By implementing a production management system, we have established thorough quality control and deliver high-quality products.

Manufacturing equipment

Located in Ashikaga City, Tochigi Prefecture, Yamada operates three factories in a vast space, equipped with the latest facilities that we are pleased to introduce.

TruMatic 7000

This is a TRUMPF machine for punching out metal sheets. With its excellent beam quality, it enables highly precise cutting. In addition, it can automatically load, unload, and sort parts, contributing to shorter delivery times.

TruLaser Tube 5000

This is the latest TRUMPF machine for pipe blank processing. It offers short processing times and supports a wide variety of pipes. Equipped with a bevel-cutting option, it enables angled cuts up to 45°, contributing to shorter delivery times.

TruLaser Tube 3030 fiber

This is an 8kW high-output TRUMPF fiber laser processing machine. It handles not only thin sheets but also thick mild steel plates, contributing to excellent edge quality. With its collision-avoidance function, it ensures high safety and maintains high operating rates, helping to shorten delivery times. In addition, a highly efficient chiller that uses water instead of chemical refrigerants is employed for cooling both the laser and the machine. Combined with a new nozzle design that reduces nitrogen consumption by up to 70%, it also contributes to environmental protection.

HG1703

This is an AMADA machine for bending processes. Since it is connected to the office network and stores data on the server, it contributes to shorter lead times for repeat products. With a maximum press capacity of 170 tons and a load control function, it ensures highly precise processing. Moreover, it enables deep bending of high difficulty, making it possible to handle a wide range of requirements — from small to large parts, from thin sheets to thick plates.

MK-03HLV100-20

This is a Koyo Giken machine for welding processes. Fiber laser welding minimizes distortion by reducing heat effects on the material. With high energy density, it achieves deep penetration and delivers strong welds. Its high output also enables fast welding of thick plates.

Technology and Case Studies

Production Management

Yamada Quality Realized Through the Introduction of a Production Management System

At Yamada, we have implemented the production management system “TECHS-BK,” which records and manages every step of the manufacturing process from start to finish. This enables us to achieve the following three key benefits, allowing us to provide high-quality, low-cost components:

- Reducing operational errors and improving quality

- Quickly identifying the exact process stage where an issue occurred, should a defect be found

- Lowering labor costs and enabling cost-efficient production

Through this advanced management framework, Yamada ensures the highest levels of quality and reliability.

Order Process

We provide the most suitable proposals to solve your company’s challenges.

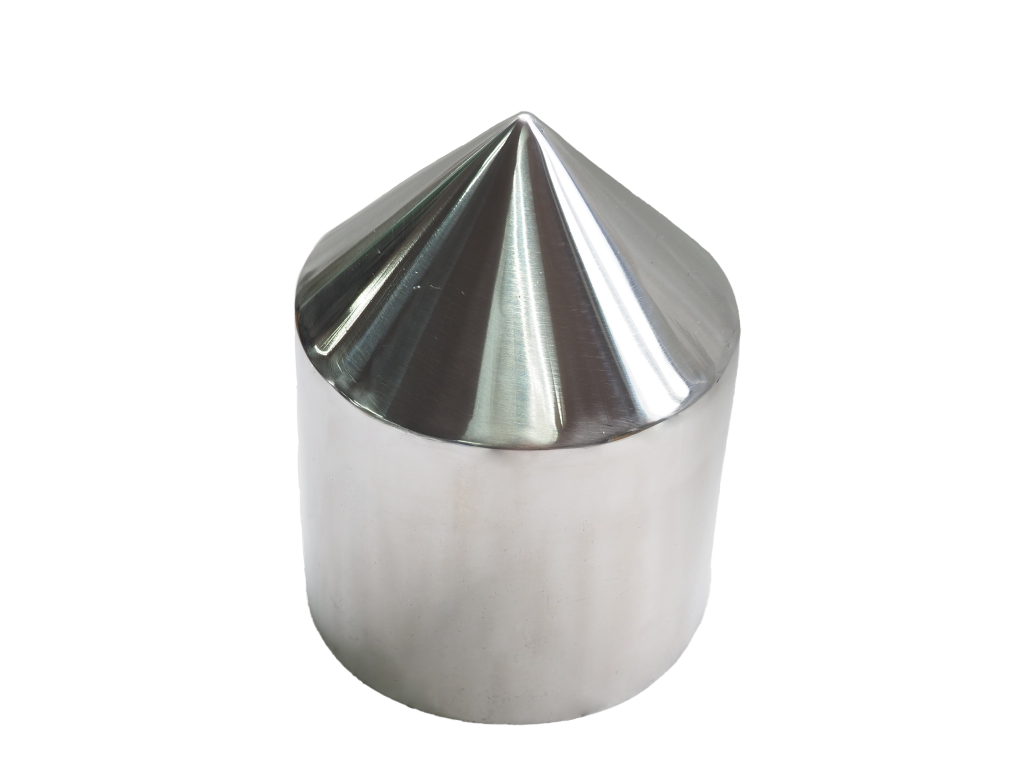

For Precision Sheet Metal Processing of Stainless Steel, Iron, and Aluminum — Yamada

Feel free to consult us — we can handle prototypes starting from just one piece!

Telephone Inquiry Hours:Weekday 8:00-17:00

TEL:0284-41-0686 FAX:0284-44-0797

Get to Know Yamada Better

Company Profile

Here you will find corporate information about Yamada Co., Ltd. We also introduce our company’s history, so please take a look.